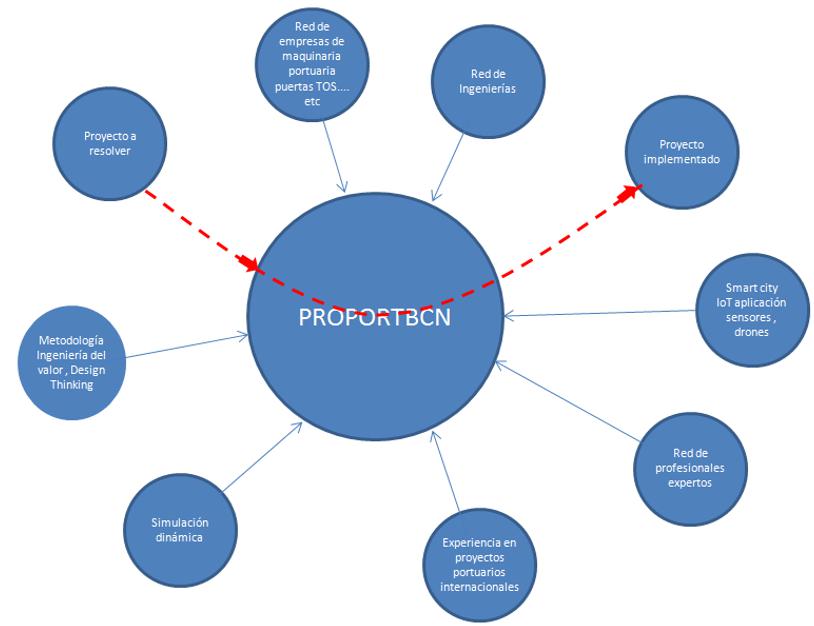

Next, we describe the services we offer, together with the network of collaborators, whose work is always supervised and integrated by ProPortBCN.

Feasibility analysis

This study concerns the definition of basic needs, estimation of investment costs, operational costs and annual revenue, with the obtaining of the EBITDA, NPV or IRR of the project by analyzing the appropriateness thereof.

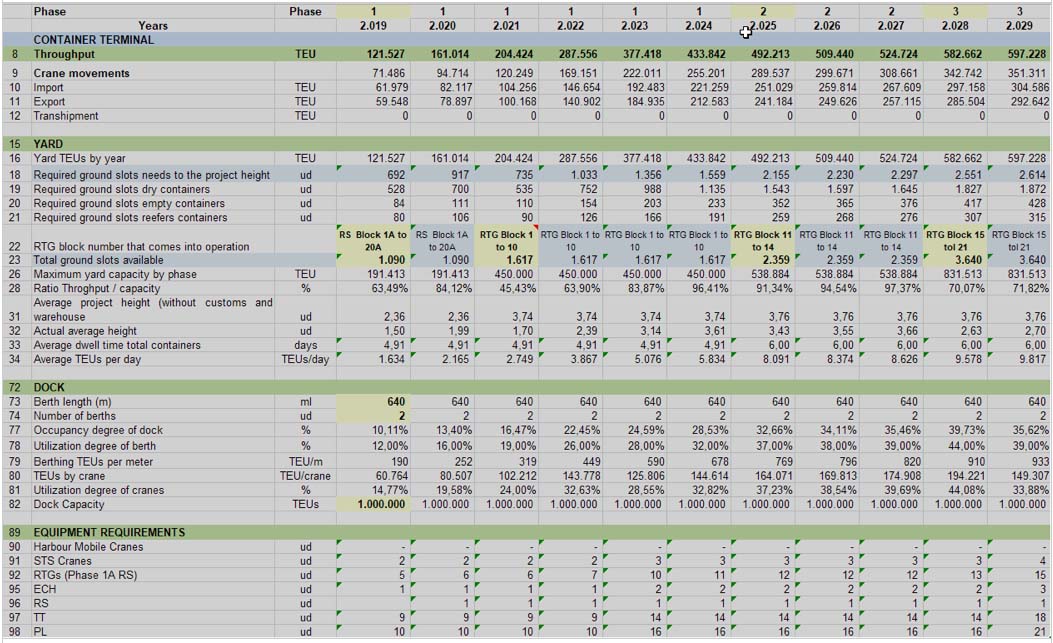

The definition of basic needs will apply studies of simulation of the type and amount of scheduled traffic, according to various scenarios and in accordance with tried and tested criteria using our experience, by making the corresponding estimates of CAPEX investment costs and OPEX operating costs.

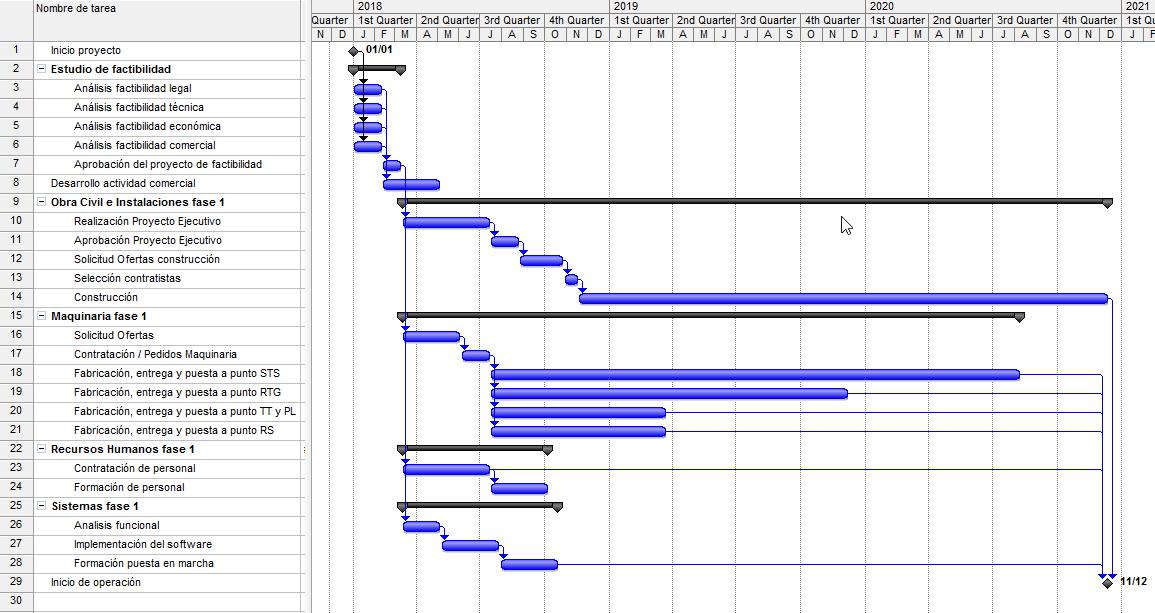

Phased example of a terminal

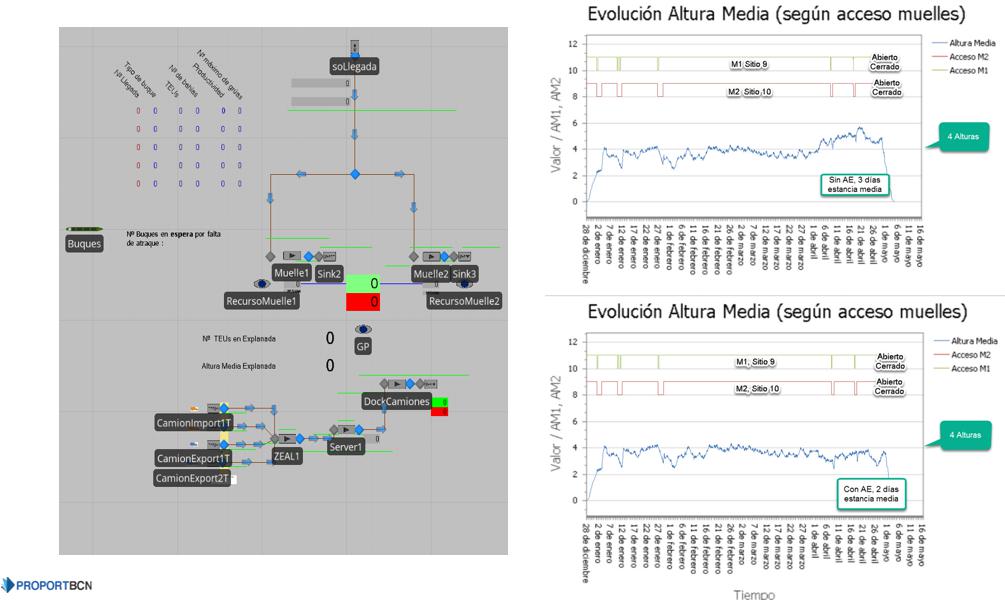

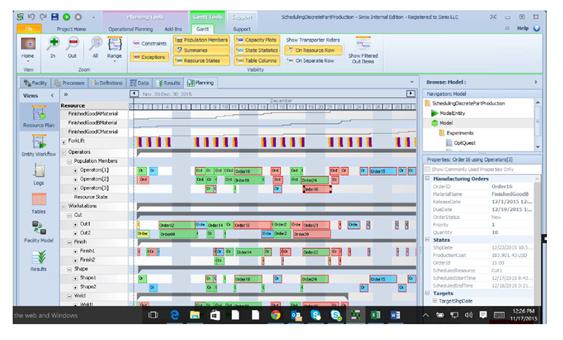

Example feasibility analysis, yard capacity based on the dock down time performed with dynamic simulation

Preliminary studie of alternatives of the Terminal

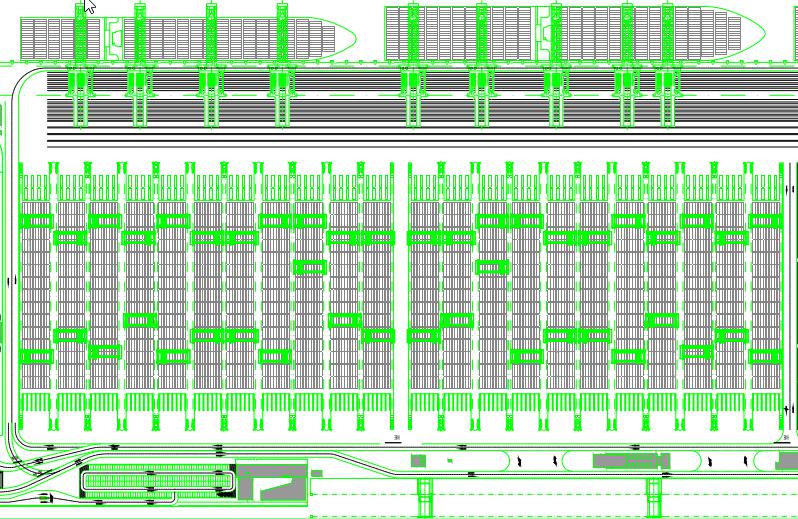

Establishment together with the representation of the client, of the requirements to be considered in the project on the basis of basic and specific needs allowing you to take the most suitable technical solution according to the objectives of the project, estimated cost and execution time.

Alternatives of machinery and equipment of the terminal are analyzed on the basis of the feasibility study, making recommendations and reaching more accurate investment costs.

Buildings, facilities and alternatives are defined in their basic aspects of design, so it refers to the structure, architecture and electrical and mechanical installations in order to establish a tighter budget.

Example analysis of layout alternatives

Basic and administrative project of the Terminal

Development of the selected alternative, together with advancements in the aspects of engineering and architecture come together in the operation of the facility.

The project is carried out in such a way that optimally meets the various clauses of the specification of the port authority.

Here is a cost estimate on the basis of drawings and specifications of the project and the premeasurement of facilities and equipment.

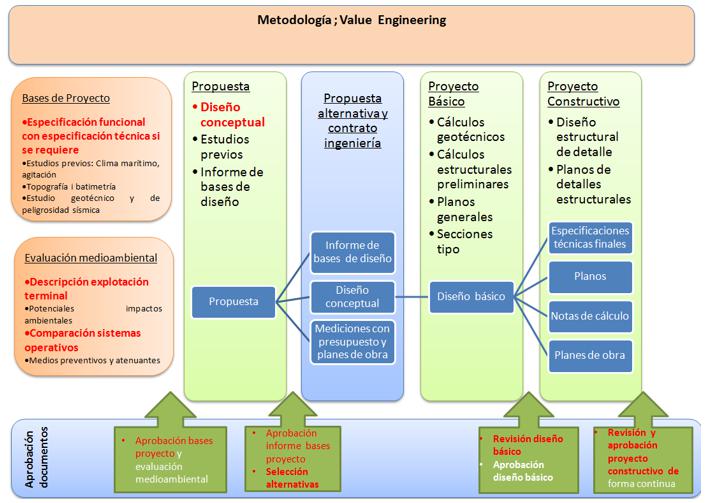

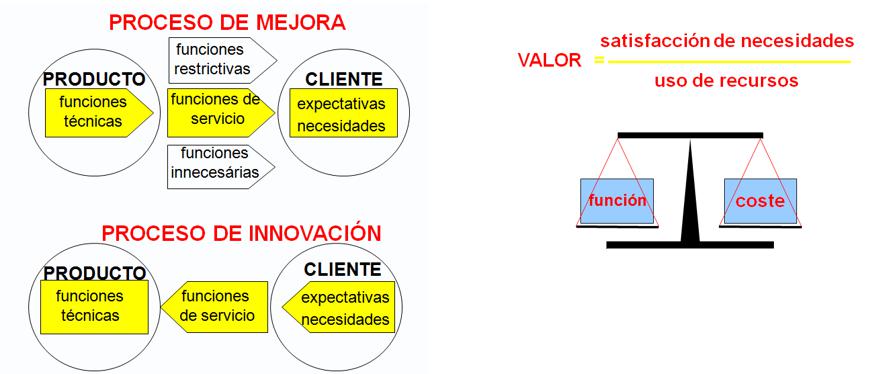

We use the value engineering methodology, Value Engineering, which is based on the definition of the starting hypothesis of the project through the project assumptions, carried out from the functional point of view, with precise technical definitions (when required) so that the consulting engineering, together with the client, the construction company and other possible collaborators and suppliers, can propose design alternatives to select the most efficient solution in the environment of the project to be carried out:

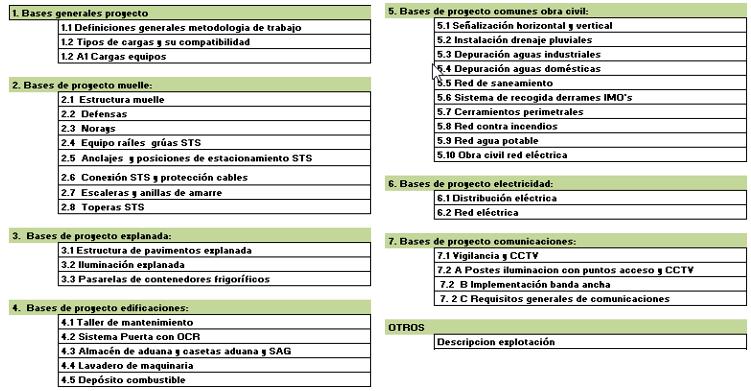

Project assumptions of construction and facilities

To facilitate and to avoid errors and interpretations in the development of the Executive project (most significantly project databases that define the functional and technical specifications that gather all of the operational aspects of the exploitation of the terminal whole) the following criteria will be applied during the concession period : dimensions, special equipment, loads of machinery, cycles or points of use, limitations, regulations, environmental… .etc.

The most significant project databases are:

Technical specifications, tender and procurement of machinery

This service corresponds to phase 1 of the implementation of machinery of:

Specification details, based on standards, concepts and technical solutions industry-standard adapted to the customer’s needs and specificities of place, which will result in the contractual specifications.

Development of model contract with their guarantees, penalties and measurementmethodology.

Technical support in the preparation of the contract to the Legal Department and theirsubsequent negotiation with suppliers.

Launch of the Tender with its publication, receipt of tenders or proposals analysis, comparative according to previously defined ratings and scoring, with recommendationreport models.

Recruitment; negotiating with finalists and signing of contract.

Project implementation and detail engineering

In the period between the request for the permits and their concession, the ExecutionProject is carried out, based on the project databases, preparing all the plans, calculations, specifications, measurements and budgets for the total definition of theproject.

The resulting product, based on the project bases, is a complete and integrated project, in which each and every one of the installations and equipment has been contemplatedand design errors and incompatibilities and interferences have been eliminated to a largeextent. between constructive elements and productive systems.

ProPortBCN can manage the whole project by contracting and supervising the detailed engineering, or give the support of review of the executive project from the functional point of view, to verify that it complies with the assumptions of loads, cycles, functions of uses …. etc. defined in the project databases, to which it is possible to add, give the support of the revision of the structural, hydraulic and electrical topics. , with contrast engineering partner.

Management of the construction and implementation of the project

Management of a complete project and implementation is the same. This can be from a project of gates from access or scanners of x-rays, to a setting in operation of a Terminal or extension of dock.

Example of application of dynamic simulation in construction risk control.

Management of the machinery manufacturing and implantation

The support of ProPortBCN in this second phase of machinery, includes Project management and technical support from the first payment (downpayment) until the final acceptance of the last of the machines.

This is, technical discussion, review of plans and calculations, design review meetingsof both STS and RTGs, RMGs, ASC … etc, supervision and monitoring of the externalmanufacturing supervisor, visits during manufacturing or preshipment tests, periodicreporting, coordination, preparatory reception equipment, monitoring commissioning, acceptance tests, checklists.

We can coordinate the supervision of manufacturing and commissioning work, usually contracted to a specialized manufacturing supervising company. It does not include the supervision of the ocean transport project and the fastening.

Projects of continuous improvement and lean manufacturing

We perform internal diagnostics and audits of existing operations and systems, proposing self-financing improvements in processes, systems, machinery and facilities.

We are always aware of new technologies and solutions in the ports sector to offersolutions that help reduce labor risks and improve the efficiency of processes.

By knowing perfectly the work processes in the ports, as well as the technology available in the industry, we work together with leading suppliers to adapt this technology to the specific problems of our processes, such as access management projects, identification of vehicles through RFID, implantation of new sensors etc.

We apply the methodology of value analysis with a high emphasis on the functional analysis of processes.

Operational simulation projects

The simulation is a tool that allows to represent in the computer the behavior of the system of an industrial port. With it it is possible to answer questions of the type what would happen if? What benefits do we get if we expand the terminal, the yard, the pier line? Is it advisable to invest in the purchase of a new crane? What is the best equipment for this terminal? What is the real need for transfer places? For how many hours is the equipment used? What is the size of the space needed for the parking of trucks? How many truck doors are needed, how many tugs, how many port workers … etc? These are some of the questions, among many others and more complex, that the simulation system is capable of solving in the virtual world before the changes are implemented in reality.

It is much shorter and less expensive to check the effects of changing machine variables dimensions etc. on the computer than to test directly on the actual system itself.

With the available software and with the power of current computers it is possible to reproduce, even graphically, how different types of systems evolve through simulationmodels and to evaluate different scenarios with the models before implementing them in reality.

Together with our collaborators, we have made simulation models for discrete events in port operations that allow us to see the operating sensitivities for operating scenarios byviewing sensitivities of the variables introduced, with models of Dock, Gate, Yard andTerminal set.

Training

Capsule port training of: capabilities, layout, project databases, lean and smart port, continuous improvement, functional analysis, value engineering, operating systems, machinery, indicators KPI and simulation.

This training is advised to be done with the terminal Team giving rise to a doublefunctionality: the training and the application and optimization of terminal

Training opportunities will be facilitated via online WebEx meetings or through Skype , via slides and videos.